Grinding: Introduction: Grinding is a finishing process used to improve surface finish, abrade hard materials, and tighten the tolerance on flat and cylindrical ...

Grinding Process Solutions imports from Butzbacher Gmbh in Germany through the port of ... ON 1 PALLET GRINDING WHEELS HS CODE:680422. Bill of Lading: .

An investigation of the material removal process in grinding glass and the effects of the grinding process on the surface structure and fracture strength of the ...

The centerless grinding process is ideal for finishing small cylindrical metal parts that require a tight tolerance and highvolume production.

Plated Grinding Applications for Horizontal Machining Centers. In this webinar, Makino''s Process Development engi... View webinar

With a reputation as being the best precision grinding companies in the country, we combine knowledge and experience with the latest technology available to date.

Industrial challenges in grinding ... Grinding as surface generation process All abrasive finishing systems are intended to ''''generate surfaces.''''

Grinding Roughs Out a New Niche Tyrolit Advocates a Patented Grinding Process for Rough and Finish Machining of Aerospace Parts. In the past, grinding has been a ...

GRINDING MACHINES Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel. When

Machines and Software. HAAS customers know that we not only sell hightech grinding machines, but also the matching grinding process to go with it.

201159 · Slag Cement Prepared by Separate Grinding Process Jin Zhigang (Shandong Province Building Materials Industrial Design and Research Institute, Jinan 250022 ...

Manufacturer of grinding wheels and superabrasive tools | | | | ...

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Handcranked knife ...

Download Pdf. machine is that, it is using a grinding wheel which is rotor in nature and operating, machine Number two, Cylindrical grinding machine Three, internal ...

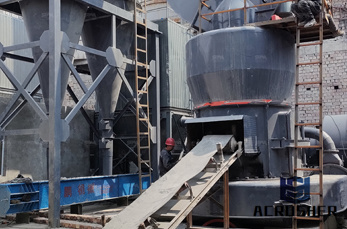

Cement grinding – Vertical roller mills versus ball mills Introduction. Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in ...

The TAIKO process is the name of a wafer back grinding process that uses a new grinding method developed by DISCO. This method is different to conventional back grinding.

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

Process optimization is an essential exercise for today''s evolving and adapting machine shop. Increasing international competition, short part runs and needit ...

i Worcester Polytechnic Institute Signature Analysis of OD Grinding Processes with Applications in Monitoring and Diagnosis By Wei Tian A Thesis

Products that contribute to back grinding processes such as back grinding tape, laminators, and removers etc. ... Adwill Top > Products for Back Grinding Process.

A twodimensional mathematical model for the thermal aspects of a grinding process is presented. The model includes heat conduction in the grinding wheel, workpiece ...

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a type of machining using an abrasive wheel ...

Concrete Grinding and Polishing | Benefits of Concrete Floor . Concrete grinding and polishing is the term used to describe the process of smoothing down rough ...

Grinding definition, to wear, smooth, or sharpen by abrasion or friction; whet: to grind a lens. See more.

WhatsApp)

WhatsApp)